A Vertically Integrated Manufacturing Company Specializing in

Product Line Development and High Volume Toll Processing

Laser Cutting

Capabilities few can match.

Four TRUMPF laser cutting systems offer you power to 5 kW, processing 1" mild steel, ¾" stainless and 5/8" aluminum within a 60" x 120" working range incorporating automated load/unload and unattended operation.

To further remove cost, your parts can be rotated or placed in any direction optimizing material utilization and machine efficiency.

Whatever your needs may be, Carnegie Manufacturing has the capability to laser cut parts to your exacting specifications.

Equipment List

- Amada Ensis 3015 9K Fiber Laser

- Trumpf L4050 - 6000 watts with load/unload and 72" x 144" bed

- Trumpf L3030 - 4000 watts with lift master and 60" x 120" bed

- Trumpf L3050 - 5000 watts with lift master and 60" x 120" bed

- Mazak Space Gear 2D/3D - 4000 watts and 60" x 120" bed

Welding / Robotic Welding

Strength, fit, and finish guaranteed perfect

From start to finish, if it's accuracy, consistency and quality you want in meeting your welded part specifications, Carnegie Manufacturing is your solution.

When your projects require MIG/TIG welders certified to AWS D1.1 standards or ROBOTIC welding, Carnegie Manufacturing's fixturing expertise and process controls ensure consistency from the first to last weldment.

Contact us today to discuss your welded parts projects and how you too can eliminate the risk of weldment failure.

Equipment List

- Lincoln Cobot Welding Systems

- Lincoln System 55 Robotic Welder

- Panasonic Robotic Welder

- Five Lincoln Power Mig 350

- Five Miller Delta 452 Mig

- Miller 350 Tig

- Two Nelson Series 4800 Stud Welder

- H & H 120 KVA Spotwelder

CNC Punching

Minimizing tooling and production costs

With the ability to rotate a full 360 degrees to punch, cut, form, mark or tap your parts, Carnegie Manufacturing's state of the art CNC Punching cell has a 50" x 100" working range (without repositioning) and can automatically load/unload up to .25" x 48" x 96" sheet sizes without operator intervention.

Additionally, by using standard sheet sizes, your parts can be nested to optimize material utilization, machine efficiency and production cost. When you combine high efficiency equipment and operational know-how with tooling capacities ranging from 19 to 190 tools, it's easy to understand why Carnegie Manufacturing is positioned to meet your most demanding prototype to high production run part requirements.

Equipment List

- Trumpf TruPunch 2020 with Sheet Master 20 ton and 50" x 100" bed without repositioning

Bending

Forming options that cut costs.

From components that require one bend to those that demand complex multiple bends, Sabina's 6 axis - CNC controlled - back gauged - 250 ton press brake cell can flawlessly form your parts to their exact drawing specifications.

For any type of forming and metal bending you require including V-bending, Radius-bending, Acute-bending, Hem-bending, Offset-bending or Emboss-bending, from light or heavy gauge material, you can count on Carnegie Manufacturing to deliver.

Call today and learn why electronically storing your part bending sequences and special processes produce outcomes that save you time and money.

Equipment List

- Safan Darley- 110 ton 10'

- Safan Darley- 150 ton 10'

- Niagra Hydraulic-175 ton 12'

- BAYKAL 265 ton with 6 axis NC back gauge and 13.5' bed

- Amada 90 ton with 4 axis NC back gauge and 8' bed

- Amada 80 ton with 4 axis NC back gauge and 8' bed

- Amada 140 ton with 6 axis NC back gauge and 10' bed

Metal Stamping

Single hit to progressive

Using both manual feed and coil feed lines Carnegie Manufacturing offers stamping processes that can satisfy your high volume sheet metal part requirements.

Ten stamping presses ranging from 32 tons to 150 tons are used in conjunction with special universal units, holders and fixtures to manufacture your custom metal stampings. Parts of any shape can be blanked, pierced, formed, stenciled, drawn and extruded using Carnegie Manufacturing's special stamping methodologies.

Next time your metal stamper comes up a bit short contact Carnegie Manufacturing to discuss your needs.

Equipment List

- Bliss 45 ton with 22" x 32" bed

- Minster 32 ton with 15" x 24" bed

- Minster 32 ton with 14" x 25" bed

- Minster 60 ton with DIE-NAMIC 6" x 12" fixture and 21" x 32" bed

- Minster 150 ton with 32" x 42" bed

- Minster P2 30 ton with 19" x 24" bed

- Minster P2 45 ton with 24" x 36" bed

- Minster P2 100 ton with 31" x 48" bed

- Verson 45 ton with 24" x 33" bed

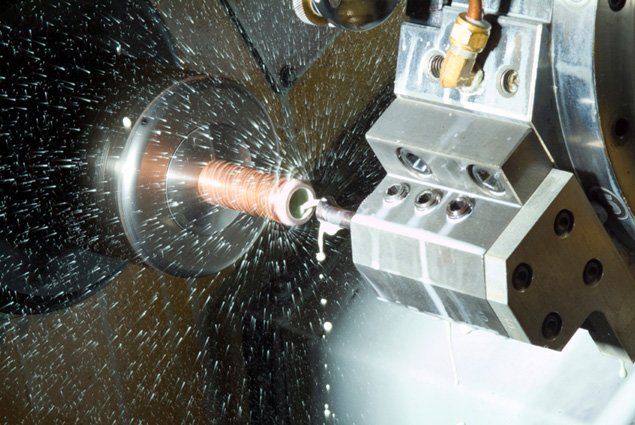

Machining

Machined, tapped, countersunk, counter bored, turned, or reamed parts.

With features like dual automated pallet changers, unattended operation and other high-productivity options, Carnegie Manufacturing's Haas vertical machining center can accurately machine your toughest jobs in less time for a lower cost.

At Carnegie Manufacturing, we have the machining capabilities to produce parts to your drawing requirements.

Reduce your machined part costs by contacting Carnegie Manufacturing today.

Equipment List

- Bridgeport Milling Machine (Acer)

- Clausing Drill Press

- (2) Haas VF-4 Machining Center w/ pallet changer

- MSC 711vs Drill Press

- MSC Bench Drill Press

- Two Solberga Drill Presses

- Wilton 15" Drill Press

- Two Wilton Tapping Systems

Powder Coating

Finishes that set you apart.

Nothing illustrates attention to detail more than your product's finish. If you rely on your contractor to provide powder coating, painting, plating, heat treating or any other type of finish, you can trust Carnegie Manufacturing to deliver these value added processes.

Whatever finish you require, Carnegie Manufacturing can help you and your products look their best. Contact us today.

Equipment List

- Automatic and Manual Spraying Capabilities

- Large capacity 3'x5' opening

- Part length up to 20'

- 3 stage wash system

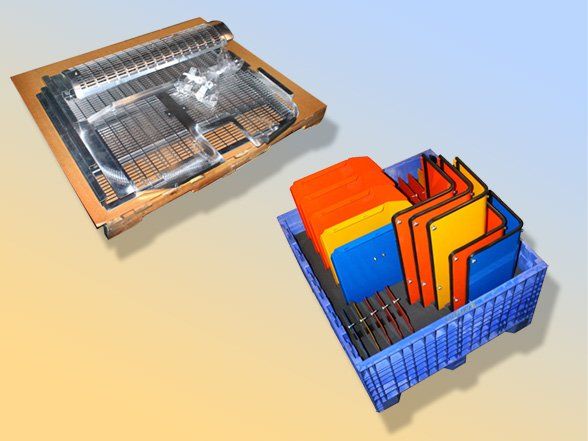

Assembly & Kitting

Programs designed to maximize your production strategies.

From JIT programs that provide your in-house assembly team with kitted components in reusable containers to full assemblies drop shipped to your customers, Carnegie Manufacturing offers a wide range of assembly options structured to help you more easily meet corporate objectives.

Regardless of what your assembly needs may be, Carnegie Manufacturing has the experience and the desire to help you succeed.

Contact us to discuss your assembly needs and options that are just right for you.

Engineering & Quality Support

From design through production

As part of our ongoing commitment to you the customer, from consulting on design for manufacturability to modifying production equipment and systems for peak efficiencies, Carnegie Manufacturing engineers continually research ways to reduce cost and improve your bottom line.

From project inception to final delivery, you'll enjoy a collaborative engineering relationship suited to your specific needs. Initiating and maintaining a close working partnership delivers done right the first time outcomes that save you time and money.

Experience the difference quality engineering support can make. Contact us to create a plan guaranteed to meet your needs.

Mill Direct Steel

As a large player in the tri state steel market Carnegie Manufacturing is able to purchase steel mill direct.

With two inhouse cut to length lines we are able to process steel coils to custom lengths which drastically increases efficiencies through the manufacturing process.

We are truly a one stop shop.